Digitalisation has transformed almost innumerable industries around the world. But, until now, the chemicals industry has been relatively slow to adapt. As leading companies explore digital capabilities like AI, Machine Learning and the Internet of Things, this traditional vertical is being turned on its head – putting competitive pressure on the rest of the market.

Innovation has always been a major driver of change in the chemicals industry, and as we look towards the future, that change is set to become faster, and more significant than ever.

Key digital technologies – including the Internet of Things (IoT), Machine Learning (ML), and Artificial Intelligence (AI) – are helping companies in the chemicals sector innovate and make decisions incredibly quickly. By giving chemicals companies the power to collect and learn from huge volumes of data at speed, they’ve significantly cut the time it takes to turn insights into action – increasing the velocity of change across the industry.

Beyond simply accelerating change, digitalisation is also helping to transform core operations for many chemicals companies. From supporting smarter R&D initiatives focusing on new material development and enhanced lab practices, to driving continuous process improvement, these innovations are enabling the industry to deliver robust performance and attain higher profits amidst intense competition – quickly becoming essential capabilities for any company that wants to remain competitive today.

Technology application and adoption

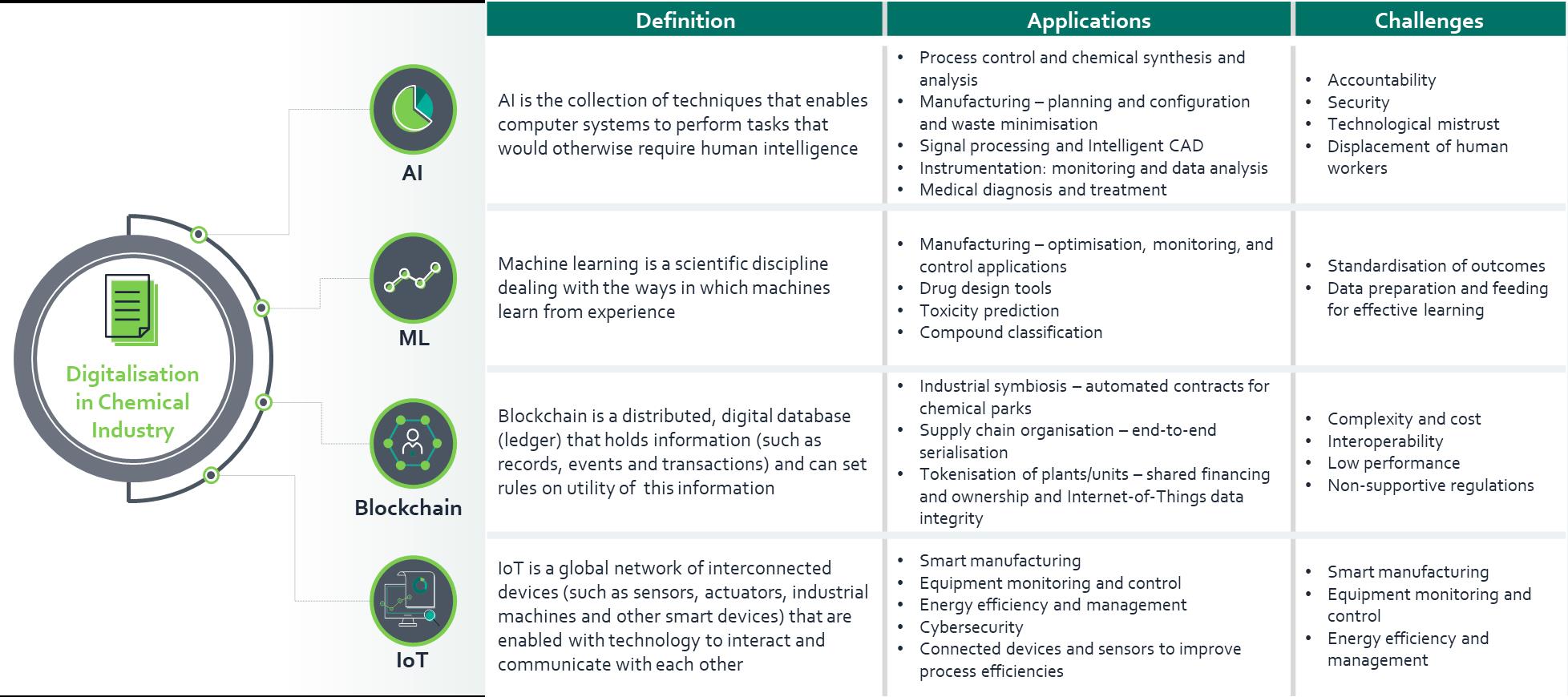

The four most significant forms of digitalisation impacting the chemicals industry are Artificial Intelligence, Machine Learning, Blockchain, and the Internet of Things. The table below gives a brief overview of the applications and challenges associated with each:

[1] ‘Blockchain in the Chemical Industry’, International Journal of Trend in Research and Development (March 2018)

[2] ‘Internet of Things in the Chemical Industry’, IJARSET (November 2017)

[3] ‘Machine Learning in Chemical Industry’, IJARSET (November 2017)

[4] ‘Artificial Intelligence in Chemical Industry’, IJARSET (October 2017)

The use of digital tools like these is expected to enhance margins by up to 9% in the chemicals industry. But practically, the ways that chemicals companies achieve those margin gains using new digital tools will look very different. Across the industry, we’ve already seen a wide variety of exciting and innovative use cases emerge in the past couple of years:

- BASF and Dublin-based biotech company Nuritas have collaborated to develop the first bioactive ingredient (peptAIde) using a mixture of AI and machine learning

- BASF and US-based materials informatics platform Citrine Informatics co-operated to use machine learning and AI to accelerate development of environmental catalyst technologies and fast track new material discovery

- Total SA and Google Cloud signed an agreement to jointly develop AI solutions applied to subsurface data analysis for oil and gas exploration and production. It will be used in applications such as production profile forecasting, automated analysis of satellite images, and analysis of rock sample images

- DowDuPont (previously Dow Chemical Company) partnered with Canada-based machine learning and computing company 1QBit to develop quantum computing tools to enhance their material sciences and chemical research. This will be carried out using machine intelligence and purportedly hardware-agnostic software

BASF and Hewlett Packard Enterprise announced a partnership to develop a revolutionary supercomputer to be used for industrial chemical research at Ludwigshafen (Germany). BASF will reduce costs and product time to market by accelerating the design of new polymers with pre-defined properties and simulating processes on catalyst surfaces more precisely

Partnerships are shaping the way forward – for now

All these examples bring us to one clear conclusion: that the future of the chemicals industry will be shaped by powerful partnerships between leading chemicals experts, and innovators in digital technology.

For chemicals companies, embracing powerful technologies like AI and ML represents a significant culture and skills-based shift – forcing them to become experts in new, highly-technical areas. But, by leveraging partnerships with the organisations that are leading these digital innovations, they can merge their expertise and bring new tech-driven projects to life quickly.

That’s great for the biggest players in the industry like BASF and DowDuPont that can use their size and resources to create and support those partnerships. But for the smaller companies in this space, building those kinds of partnerships won’t always be an option.

For them, the digital future seems somewhat unclear. Today, they face tough decisions between sticking close to the traditional processes in which they’re already experts, or branching out to develop new digital skills themselves. It’s a complex choice, and one without a clear right or wrong answer.

The data generated will be integrated with UK Biobank’s patient details and de-identified medical and health records to understand the links between genetic variation and diseases.

Platforms hold the answer for many

Fortunately, chemicals companies of all sizes may not need to rely on private partnerships with major technology companies for long. The availability of innovative platforms is growing by the day, enabling almost anyone to access deep AI, ML, IoT, and even Blockchain capabilities.

In what some commentators are calling The Age of Platforms, chemicals companies will be able to access new digital capabilities for everything from R&D and materials discovery, to recommendation-based marketing and distribution of the chemicals they produce, simply by acquiring pre-built platforms from established technology vendors.

With the competitive impact of these technologies made clear by the global players and their powerful partnerships, the message to the rest of the market is clear. They must find ways of embracing these tools, exploring new capabilities, and innovating for themselves – and the rise of platforms is making that possible.

For those companies, their success will depend greatly on the platforms they choose to access these new capabilities. While there is no single “one size fits all” platform for AI, ML, or IoT, businesses can make informed decisions by carefully considering what they want to achieve with the technology before they choose a platform to bring their ideas to life.

If you’d like to learn more about how The Smart Cube can help you better understand the forces shaping the chemicals industry, please get in touch, or visit our web site to read about the solutions we provide for companies in the Energy and Chemicals sector.